At Glorious Circuit Technologies, we are a world-renowned electronics manufacturing solutions provider. We aim to provide innovative, reliable, and high-performance solutions to our customers.

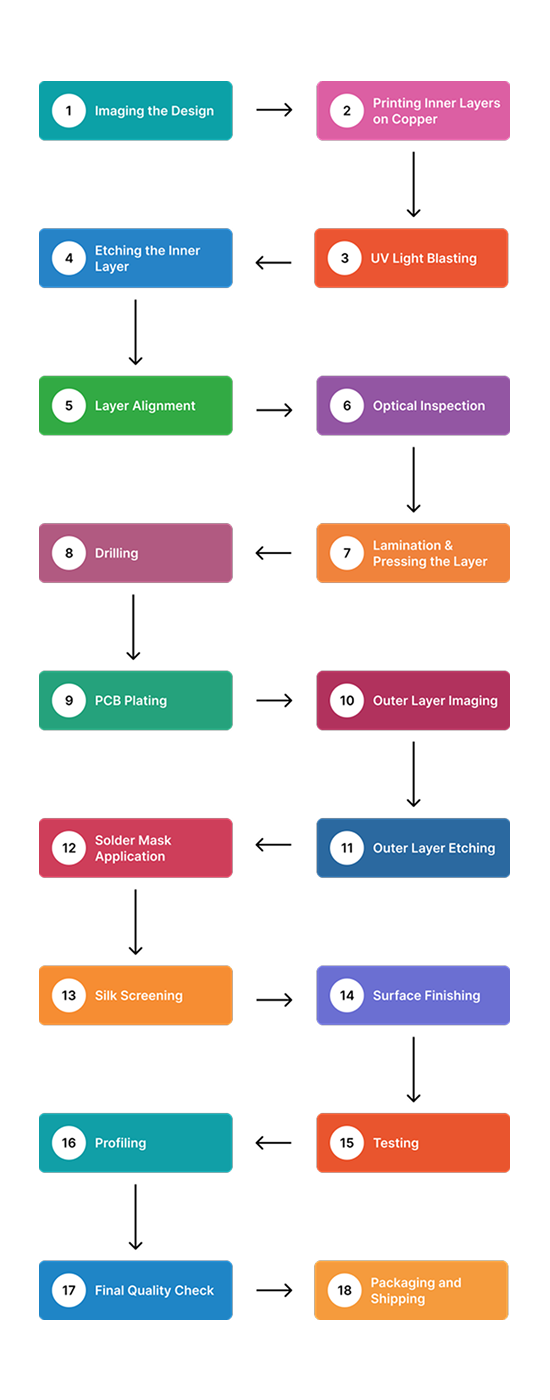

Contact UsWe make sure your product designs are optimized for smooth and cost-effective manufacturing. Our DFM expertise includes:

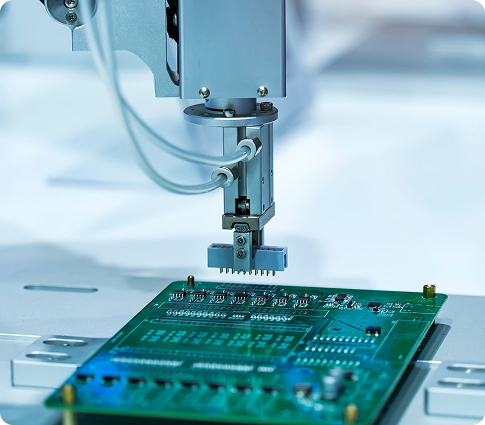

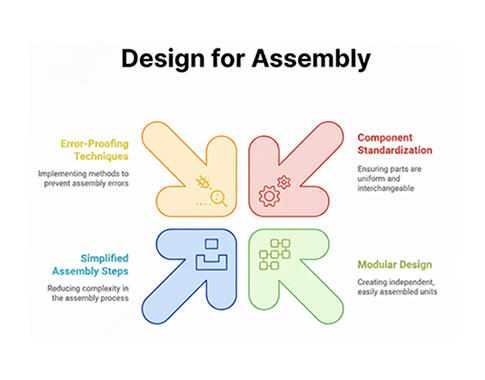

Efficient assembly reduces cost and improves consistency. Our DFA practices ensure that your product can be assembled quickly, reliably, and at scale. Our DFA expertise includes:

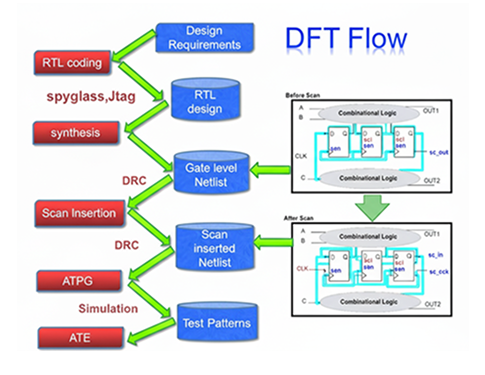

Robust testing ensures product quality and performance. Our DFT strategies allow efficient fault detection and validation during manufacturing. Our DFT expertise includes: